网站标题

Clear records

history record

Products

Industrial solid waste incineration center

Scope of Application

1.Industrial garbage (Polymer waste): plastic PE, PU, EVA, rubber (tyre), Styrofoam, plastic bottle, fiber, foam, cloth, rosin, Acrylic, leather, cowhide scurf, complex board, bakelite powder, urea powder, cabbage cloth, tape, coating, polymer, etc.;

2. Medical waste: syringes, gloves, bags, gauze, blood transfusion tubes, organs and other infectious waste;

3. General garbage: cardboard, paper chips, wood chips, leaves, etc.;

4. Special waste: waste oil, waste solvent, sludge, dust pool, paint on iron, mold filter residue, etc.;

Characteristics

1. Smokeless, odorless, no secondary public hazards;

2. No combustion-supporting agent, the natural calorific value of waste is 3000kcal/kg, and a large number of hot water, hot steam, power generation, etc.;

3. Furnace body life is 8-10 years;

4. Zero failure: low failure rate, low maintenance and operation costs;

1.Industrial garbage (Polymer waste): plastic PE, PU, EVA, rubber (tyre), Styrofoam, plastic bottle, fiber, foam, cloth, rosin, Acrylic, leather, cowhide scurf, complex board, bakelite powder, urea powder, cabbage cloth, tape, coating, polymer, etc.;

2. Medical waste: syringes, gloves, bags, gauze, blood transfusion tubes, organs and other infectious waste;

3. General garbage: cardboard, paper chips, wood chips, leaves, etc.;

4. Special waste: waste oil, waste solvent, sludge, dust pool, paint on iron, mold filter residue, etc.;

Characteristics

1. Smokeless, odorless, no secondary public hazards;

2. No combustion-supporting agent, the natural calorific value of waste is 3000kcal/kg, and a large number of hot water, hot steam, power generation, etc.;

3. Furnace body life is 8-10 years;

4. Zero failure: low failure rate, low maintenance and operation costs;

Product Details

Scope of Application

1.Industrial garbage (Polymer waste): plastic PE, PU, EVA, rubber (tyre), Styrofoam, plastic bottle, fiber, foam, cloth, rosin, Acrylic, leather, cowhide scurf, complex board, bakelite powder, urea powder, cabbage cloth, tape, coating, polymer, etc.;

2. Medical waste: syringes, gloves, bags, gauze, blood transfusion tubes, organs and other infectious waste;

3. General garbage: cardboard, paper chips, wood chips, leaves, etc.;

4. Special waste: waste oil, waste solvent, sludge, dust pool, paint on iron, mold filter residue, etc.;

Characteristics

1. Smokeless, odorless, no secondary public hazards;

2. No combustion-supporting agent, the natural calorific value of waste is 3000kcal/kg, and a large number of hot water, hot steam, power generation, etc.;

3. Furnace body life is 8-10 years;

4. Zero failure: low failure rate, low maintenance and operation costs;

5. Easy to operate, easy to learn, easy to burn, labor saving

6. Negative pressure design, no backfire, continuous feeding, large handling capacity;

Hazardous waste handling capacity:50-5000kg/h

Malaysia Industrial Waste Centralized Treatment Center

Industrial hazardous solid waste is sent into the combustion chamber of the furnace body by a hydraulic push device, ignited by a primary burner, and fully oxidized and heated in the combustion chamber (600-900°C) of the furnace body according to the principle of combustion 3T (temperature, time, eddy current). The residual exhaust gas enters the secondary combustion chamber and is pyrolyzed at high temperature (1000-1100°C) to achieve the complete combustion effect of no peculiar smell, no foul smell, and no smoke, so that the combustion destruction removal rate is over 99.99%. The cyclone dust collector removes large particles of dust and then enters the waste heat boiler to cool down and recover steam.

The cooled flue gas directly enters the quench tower, where it is sprayed with lye, and the temperature is lowered to below 200°C within 1 second to prevent the re-generation of dioxins, and at the same time remove the acid gas in the flue gas. Then, slaked lime activated carbon is sprayed into the Venturi reactor to remove acid gas, heavy metals and dioxins in the flue gas. The flue gas then enters the bag filter to remove fly ash, waste activated carbon and other particles, and finally the flue gas enters the spray scrubber to absorb and remove harmful gases and small particles of dust to achieve: non-toxic, smoke-free, harmless, odorless and completely For the effect of combustion, after defoaming treatment, the exhaust fan will introduce the treated gas up to the standard into the chimney and discharge it into the atmosphere (below 80°C).

At the same time, there is an emergency discharge system. Once the incinerator system fails, the pneumatic switching valve will act instantly, and the exhaust gas will be emptied by the emergency discharge system to ensure the safe operation of the system.

The ashes produced after burning fall into the ash trolley and are manually transferred to the landfill for burial.

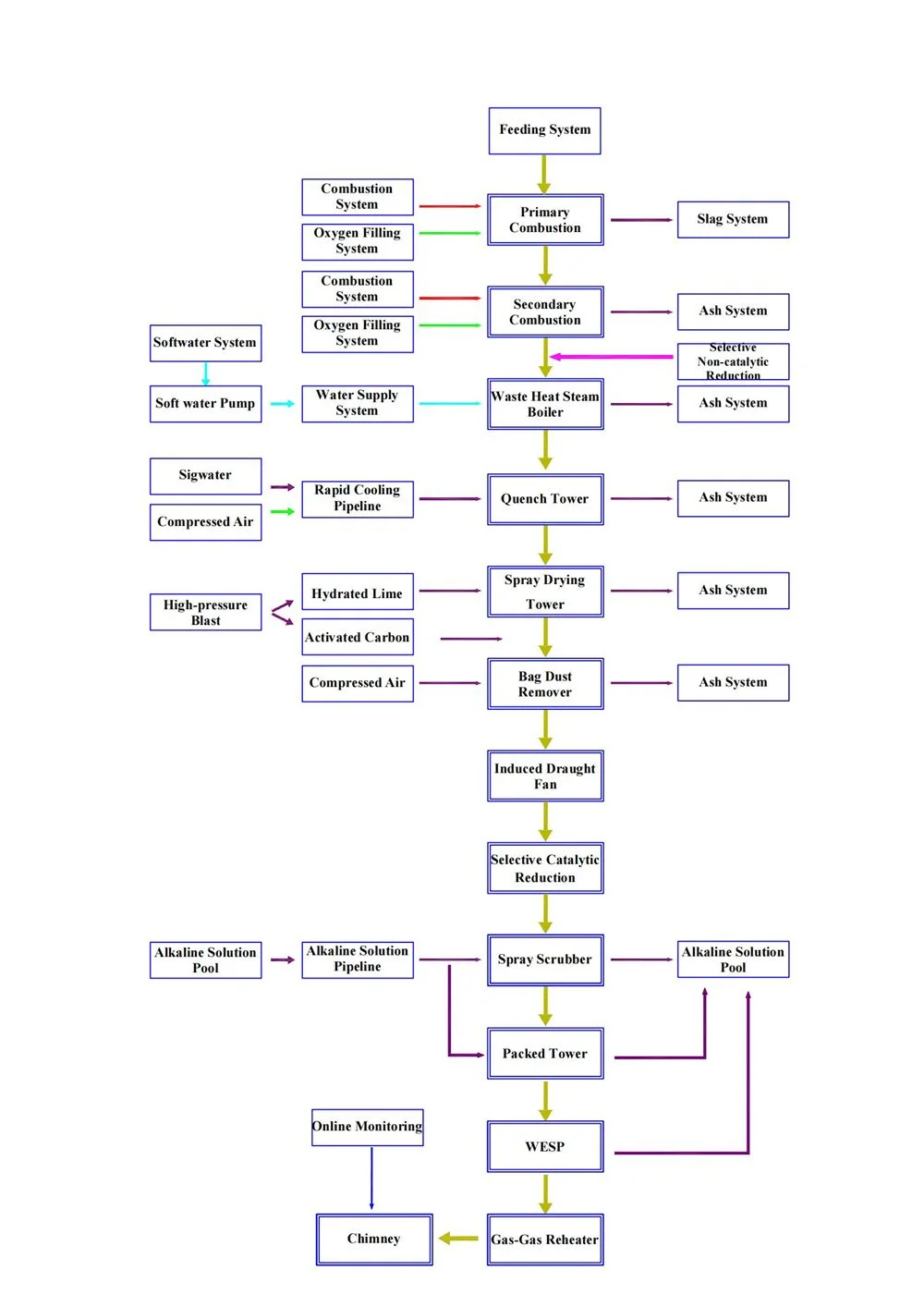

Flow chat

Online message

Related products

choose an area code

We value your privacy

We and our partners are using technologies like Cookies or Targeting and process personal data like IP-address or browser information in order to personalize the advertisement you see. These technologies may access your device and help us to show you more relevant ads and improve your internet experience.We also use it in order to measure results or align our website content. Because we value your privacy, we are herewith asking your permission to use the following technologies.

Share to WeChat

×